How Can You Validate Parylene Coverage?

Parylene XY is a transparent, thin (hundreds of nanometers to a few micrometers), well adhering, pin-hole and defect free conformal coating. They are coated uniformly on flat surfaces and component configurations with sharp edges, points, flat surfaces, crevices or exposed internal surfaces are coated uniformly without voids.

Why is Parylene tough to verify?

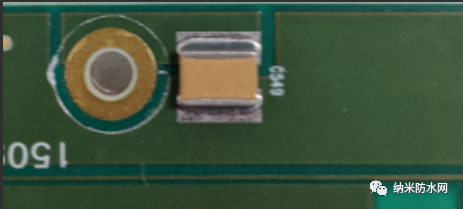

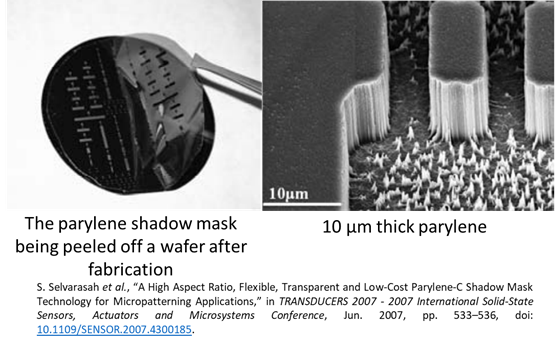

Because Parylene XY is transparent and forms a flawless / continuous layer its inspection becomes hard to the bare eye. Different types of inspection processes can be followed to verify the presence or uniformity of Parylene depending on which tools you have access to. The easiest at home inspection method is to inspect the de-masking lines. When a customer sends us a substrate for Parylene XY coating process, we receive a mask scheme along with other instructions. Masking process is necessary to protect the areas where Parylene XY must not be deposited. After the chemical vapor deposition process we carefully remove the masking material from the substrate without damaging the Parylene layer. Once the mask is removed edges of the Parylene conformal coating around the areas where a masked area and a coated area meet can be observed. You can perform this either with bare eye with a lot of care under light (watch for the reflection) or using an optical microscope (magnification) for ease. Spotting the de-masking lines is a very assuring way of validating the presence of parylene. In the Figure below, a Parylene layer being peeled off of a wafer and on the right hand-side 10 μm features are shown [1]. With a careful eye you can spot the Parylene layer from the edges on a macroscale.

Parylene is a hydrophobic conformal coating meaning that if gets into contact with water the water will not spread but form semi-spheres on the Parylene surface. If your substrate or components will not be affected by water dropping a few drops of water on the areas where Parylene must be present would give a good idea of its presence. The dewetting angle of Parylene-AF4 is 100 degrees, Parylene C is ≈80 degrees and Parylene N is ≈75 degrees [2].

Other validation methods include electron microscopy and Fourier-transform infrared (FTIR) characterization by which you can obtain a high resolution image and a chemical fingerprint of the material, respectively.

REFERENCES

[1] S. Selvarasah et al., “A High Aspect Ratio, Flexible, Transparent and Low-Cost Parylene-C Shadow Mask Technology for Micropatterning Applications,” inTRANSDUCERS 2007 - 2007 International Solid-State Sensors, Actuators and Microsystems Conference, Jun. 2007, pp. 533–536, doi: 10.1109/SENSOR.2007.4300185.

[2] “(15) (PDF) Contact Angle of Parylene AF4 on a Sapphire Substrate,”ResearchGate. https://www.researchgate.net/publication/305905712_Contact_Angle_of_Parylene_AF4_on_a_Sapphire_Substrate (accessed Apr. 28, 2020).

隨著電子產品防水需求的不斷提高,從原先的 IP54到現在的IP67IP68等級!市場上出現了防水透氣膜和防水透音膜,目前這兩種不同的材料應用被搞混了,今天便與大家一起討論防水透氣

最近各地降雨量激增,所以手機就難免會沾點水,作為生活中不可或缺的電子產品,防水已經成為一個十分重要重要功能,而且個人對目前的IP68手機市場是相當不滿意的。為什么?太貴

自然界中荷葉具有出淤泥而不染的典型不沾水特性(學術上稱為Cassie-Baxter狀態),具有自清潔、抗結冰、減阻、抗腐蝕等廣泛應用價值,而玫瑰花瓣則具有水滴高粘附特性(稱為Wenze

派瑞林各種粉材真空鍍膜技術加工 納米涂層防水處理

派瑞林各種粉材真空鍍膜技術加工 納米涂層防水處理

高阻隔強絕緣防汗液涂層藍牙耳機3C電子產品IPX7納米材料

高阻隔強絕緣防汗液涂層藍牙耳機3C電子產品IPX7納米材料

耐磨超疏水納米材料 絕緣子架空導線電纜橋梁防覆冰涂層

耐磨超疏水納米材料 絕緣子架空導線電纜橋梁防覆冰涂層

真空等離子氣相沉積技術納米防水鍍膜加工 產能5萬片天

真空等離子氣相沉積技術納米防水鍍膜加工 產能5萬片天

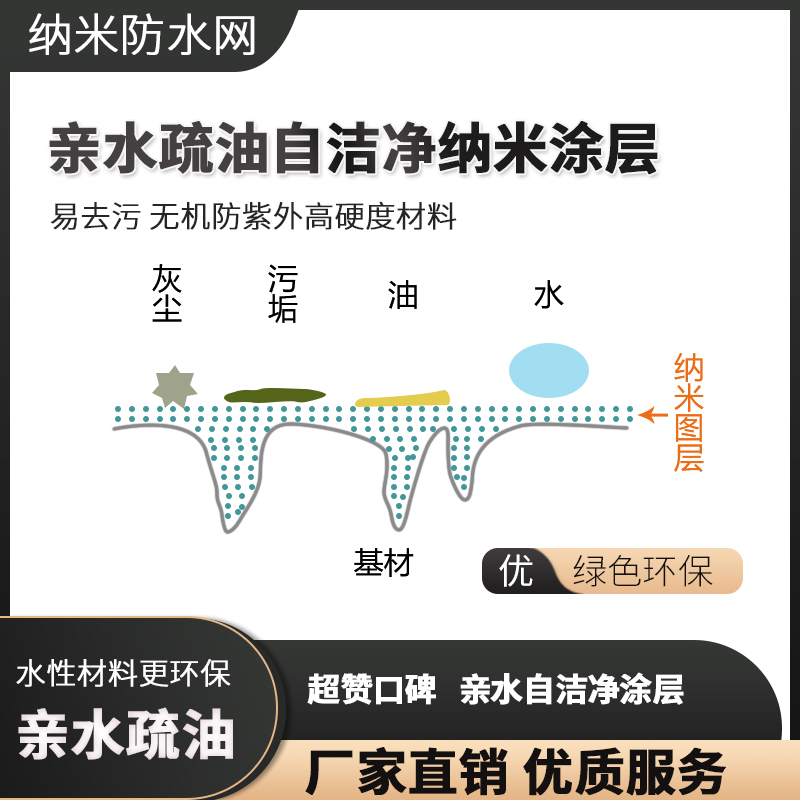

親水疏油自潔凈納米涂層 易去污 無機防紫外高硬度材料

親水疏油自潔凈納米涂層 易去污 無機防紫外高硬度材料

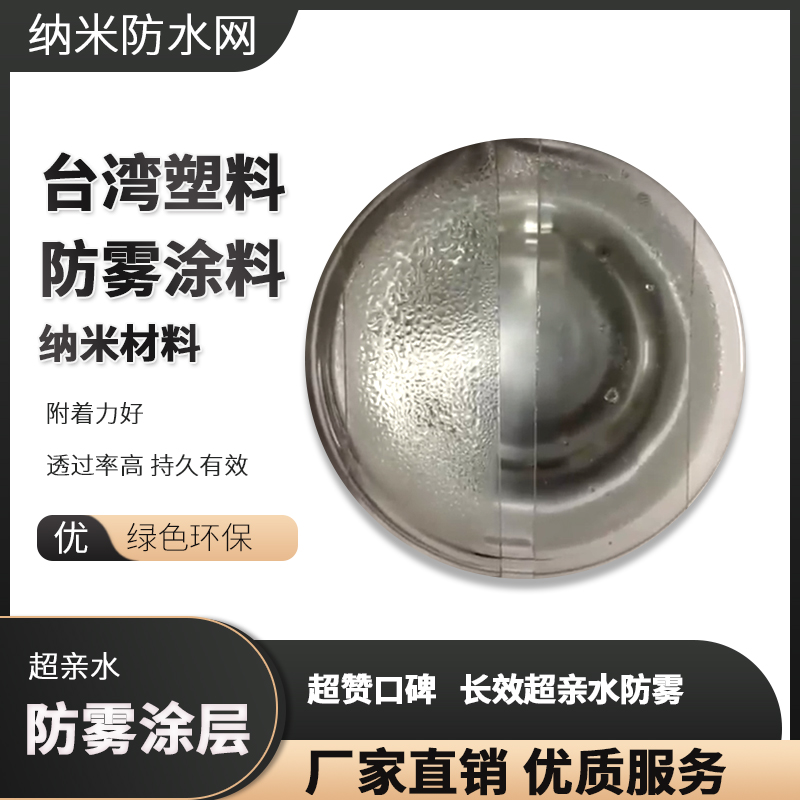

臺灣超親水防霧塑料專用 附著力好 透過率高 持久有效

臺灣超親水防霧塑料專用 附著力好 透過率高 持久有效