[派瑞林日記]Are Parylene Noodles a Defect

Are Parylene Noodles a Defect

Unlike liquid conformal coatings joined to substrate surfaces by wet application methods, polymeric parylene (XY) uses a unique chemical vapor deposition (CVD) process to assure adherence. There is no intermediate liquid phase. Rather, cross-link polymerization of powdered raw XY-dimer converts the solid to a vapor at the molecular level, polymerizing XY directly as a transparent film on assembly surfaces.

Applied in a gaseous state, XY penetrates deep within substrate surfaces, providing an authentically conformal protective covering. In many ways, parylene coatings are superior to those provided by wet materials like acrylic, epoxy, silicone or urethane, for a wider variety of products and purposes. Micro-thin film performance makes parylene especially useful for coating printed circuit boards (PCBs) and in microelectromechanical systems (MEMs)/nano technologies.

The XY deposition process assures neither heat nor cooling is needed for coating adherence. The circuit board neither expands nor shrinks, reducing coating-stress. Depositing XY as a dry vapor helps the coated items endure minimal changes during the application process, eliminating another major risk factor of coating defect.

Polymeric Noodles

As a polymer, parylene begins as a monomer-based linear chain fused covalently. The ongoing chain entanglements characterizing parylene morphology stimulate a degree of viscoelastic behavior. Viewed microscopically under normal conditions, they resemble noodles, sometimes elongated but neither precisely straight nor clustered together; often compared to a bundle of spaghetti noodles, they are held together by a few chemical cross-links. More precisely,

· the shape of a Gaussian coil develops,

· collected as parylene (or other polymer) molecules join,

· ranging from several nanometers to several tens-of-nanometers in length,

· measured by the root-mean-square end-to-end distance Ree,

· scaled as the square root of the coil‘s total number of monomers (N) or molecular weight (Mw).

In this basic form, which encompasses parylene morphology, noodles are NOT a defect, but a normal and characteristic part of the polymer’s physical structure. Increasing their density across the strands provides shape and strength, limiting their ability to pull away from each other, while increasing their functional and load-bearing uses. These capacities help XY polymers achieve architectural/performance networks necessary for conformal coating purposes.

Defective Noodling

Despite its general superiority as a conformal coating, parylene application and use can suffer defects. While common XY defects can often be identified, planned for and mitigated through proper procedures, they still occur. Inadequate application or deposition onto a surface unprepared for adhesion can compromise XY function.

Defective noodling is the result of deformation mechanisms developing on the surfaces and interfaces of parylene coated systems. These factors can cause loss of the parylene film’s surface pattern-effectiveness, disrupting the structural integrity of the coating’s typically reliable noodle-like entanglement. The surface is then characterized by highly disordered structural configuration, resembling a plate of noodles winding chaotically around each other, interfering with parylene’s usual uniform, pinhole-free surfaces. Disruption of the coating’s performance integrity can lead to both current leakage and voltage breakdown.

If inappropriately cleaned before application, or inadequately deposited, liquids or other substances can penetrate both at the parylene-substrate interface and through the polymer layer, stimulating an environment of disrupted noodle development. Film instabilities can also occur on parylene surfaces when temperatures exceed the polymer’s standard glass transition temperatures (Tg). Basic outcomes include sequential disruption of hierarchical coating formation, a condition that can be generated despite the protection usually afforded by XY’s reliable CVD application method. Poor adhesion and residual stress can also lead to bending, cracking, peeling and noodling of parylene conformal films.

Parylene conformal coating defects can be caused by a range of factors. However,

· cleanliness of the product surface,

· carefully matching the parylene type to the coating assignment/purpose, and

· expert performance of the CVD process

· mitigate the potential for these problems to arise.

Undetected trace contaminants disrupt the bond between parylene film and underlying surfaces, leading to disruption of noodle configuration.

Thus, noodles, a basic element of parylene morphology, can themselves be transformed from a tasty dish of conformal coating to one that may need to be scrapped or redone.

· Conventional, non-defective parylene noodles resemble a properly cooked and stirred pot of spaghetti, with a bit of olive oil stirred in, to keep them from only adhering to each other.

· Rather, they adhere to the substrate. This recipe can be delicious!!

· When defects occur, the noodles resemble a tangled mat of unstirred, cooked spaghetti, assuming a random shape, of little use to the conformal coating project.

Not always immediately apparent, disordered adhesion will eventually compromise the coating and, ultimately, the end-product, thus neutralizing parylene’s protective benefits. As an integral structural XY-component, you can’t avoid the presence of parylene noodles, but you can control them.

譯 文

與通過濕涂法連接到基材表面的液體保形涂料不同,聚合物聚對二甲苯(XY)使用獨特的化學氣相沉積(CVD)工藝來確保粘附。沒有中間液相。相反, 粉末狀原始XY-二聚體的交聯聚合 將固體轉化為分子水平的蒸氣,直接聚合XY作為組裝表面上的透明膜。

XY以氣態涂覆,深入滲透到基板表面內,提供真正保形的保護層。在許多方面,對于更廣泛的產品和用途,聚對二甲苯涂層優于由諸如丙烯酸,環氧樹脂,硅樹脂或聚氨酯的濕材料提供的涂層。微薄膜性能使聚對二甲苯特別適用于涂覆印刷電路板(PCB)和微機電系統(MEM)/納米技術。

該 XY沉積 過程保證既沒有熱量也不需要用于涂覆粘附冷卻。電路板既不會膨脹也不會收縮,從而降低涂層應力。將XY作為干蒸汽沉積有助于涂層物品在施加過程中承受最小的變化,消除了涂層缺陷的另一個主要風險因素。

聚合面條

作為聚合物,聚對二甲苯以共價稠合的基于單體的直鏈開始。 表征聚對二甲苯形態的正在進行的鏈 纏結刺激了一定程度的粘彈性行為。在正常條件下用顯微鏡觀察,它們類似于面條,有時是細長的,但既不是直的也不是聚集在一起; 通常 與一捆意大利面條相比,它們通過一些化學交聯連接在一起。 更確切地說,

· 高斯線圈的形狀發展,

· 聚對二甲苯(或其他聚合物)分子加入時,

· 長度從幾納米到幾十納米,

· 通過均方根端到端距離Ree測量,

· 按比例計算線圈的單體總數(N)或分子量(Mw)的平方根。

在這種包含聚對二甲苯形態的基本形式中,面條 不是 缺陷,而是聚合物物理結構的正常和特征部分。增加它們在股線上的密度提供了形狀和強度,限制了它們彼此拉開的能力,同時增加了它們的功能和承載用途。這些能力有助于XY聚合物實現保形涂層所需的建筑/性能網絡。

Noodling瑕疵

盡管其作為保形涂層具有普遍的優越性,但聚對二甲苯的應用和使用可能存在缺陷。雖然常見的XY缺陷通常可以通過適當的程序進行識別,規劃和減輕,但它們仍然會發生。 施加不充分或沉積在未經附著的表面上 會損害XY功能。

有缺陷的涂層是聚對二甲苯涂層體系表面和界面上形成的變形機制的結果。這些因素可能導致聚對二甲苯薄膜表面圖案效果的損失,破壞涂層的結構完整性,通常是可靠的 面條狀纏結。然后,表面的特征在于高度無序的結構構型,類似于一張彼此纏繞的面條盤,干擾了聚對二甲苯通常均勻,無針孔的表面。涂層性能完整性的中斷 可能導致電流泄漏和電壓擊穿。

如果在施用前不適當地清潔,或者沉積不充分,液體或其他物質可以在聚對二甲苯 - 基底界面和聚合物層中滲透 ,從而刺激面條發育中斷的環境。當溫度超過聚合物的標準玻璃化轉變溫度(Tg)時,聚對二甲苯表面也會發生膜不穩定性。基本結果包括分層涂層形成的連續破壞,盡管通常由XY可靠的CVD應用方法提供保護,但仍可產生這種情況。粘附性和殘余應力差也會導致 聚對二甲苯保形膜的彎曲,開裂,剝落和涂覆。

聚對二甲苯保形涂層缺陷可由一系列因素引起。然而,

· 產品表面清潔,

· 仔細匹配聚對二甲苯類型與涂層分配/目的,

· CVD工藝的專家表現

· 減少出現這些問題的可能性。

未檢測到的痕量污染物破壞了聚對二甲苯薄膜和下面的表面之間的結合,導致面條配置的破壞。

因此,作為聚對二甲苯形態的基本元素的面條 本身可以從保形涂層的美味菜肴轉變為可能需要報廢或重做的面條。

· 傳統的,無缺陷的聚對二甲苯面條類似于正常煮熟和攪拌的意大利面條鍋,攪拌著一點橄欖油,以防止它們僅相互粘附。

· 相反,它們粘附在基材上。這個食譜可以很好吃!!

· 當出現缺陷時,面條類似于未經過攪拌的意大利面條的纏結墊,呈現隨機形狀,對保形涂層項目幾乎沒有用處。

并非總能立即顯現,無序粘合最終會損害涂層,最終影響最終產品,從而中和聚對二甲苯的保護效果。作為一個完整的結構XY組件,你無法避免parylene面條的存在,但你可以控制它們。

更多納米防水資訊請關注納米防水微信號: nanowp

隨著電子產品防水需求的不斷提高,從原先的 IP54到現在的IP67IP68等級!市場上出現了防水透氣膜和防水透音膜,目前這兩種不同的材料應用被搞混了,今天便與大家一起討論防水透氣

最近各地降雨量激增,所以手機就難免會沾點水,作為生活中不可或缺的電子產品,防水已經成為一個十分重要重要功能,而且個人對目前的IP68手機市場是相當不滿意的。為什么?太貴

自然界中荷葉具有出淤泥而不染的典型不沾水特性(學術上稱為Cassie-Baxter狀態),具有自清潔、抗結冰、減阻、抗腐蝕等廣泛應用價值,而玫瑰花瓣則具有水滴高粘附特性(稱為Wenze

派瑞林各種粉材真空鍍膜技術加工 納米涂層防水處理

派瑞林各種粉材真空鍍膜技術加工 納米涂層防水處理

高阻隔強絕緣防汗液涂層藍牙耳機3C電子產品IPX7納米材料

高阻隔強絕緣防汗液涂層藍牙耳機3C電子產品IPX7納米材料

耐磨超疏水納米材料 絕緣子架空導線電纜橋梁防覆冰涂層

耐磨超疏水納米材料 絕緣子架空導線電纜橋梁防覆冰涂層

真空等離子氣相沉積技術納米防水鍍膜加工 產能5萬片天

真空等離子氣相沉積技術納米防水鍍膜加工 產能5萬片天

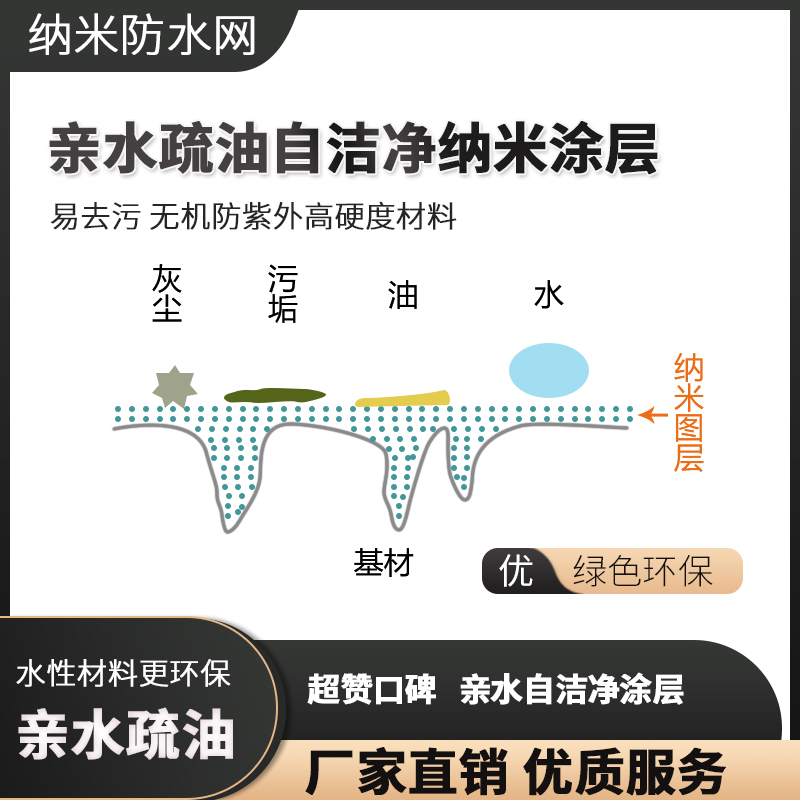

親水疏油自潔凈納米涂層 易去污 無機防紫外高硬度材料

親水疏油自潔凈納米涂層 易去污 無機防紫外高硬度材料

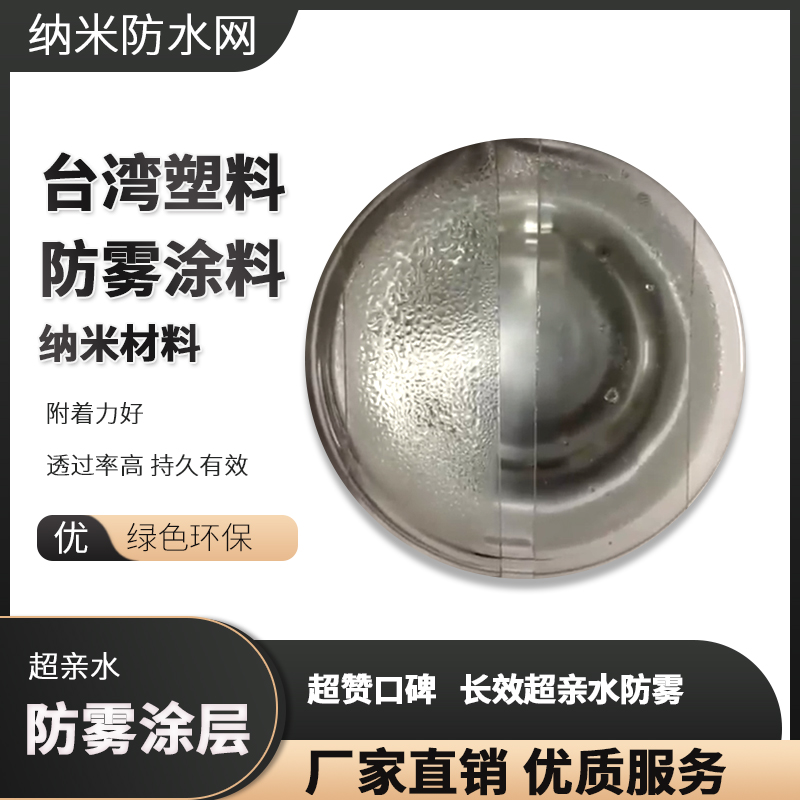

臺灣超親水防霧塑料專用 附著力好 透過率高 持久有效

臺灣超親水防霧塑料專用 附著力好 透過率高 持久有效